DIECUTTING

THE BOBST DIE-CUTTING ADVANTAGE

BOBST and flat bed die-cutting go hand in hand, after all they did invent the technology with the first Autoplaten® press, the AP 900, introduced back in 1940. From that pioneering die-cutter, right up to today’s highly sophisticated production lines, BOBST has continuously developed and improved the technology of the flat bed die-cutting process. They have achieved this by listening to the feedback of our customers, by investing heavily in research and development, and by accumulating unmatched skills and experience among our people.

The BOBST range of flat bed die-cutters (also called cutter-creasers or punching machines in some countries) is the most extensive available in the market and offers a wide choice of productivity and automation levels, in press widths ranging from a compact 76cm (30”) to an impressive 2.1m (82”). Each of the machines in the range offers a level of reliability, versatility, and performance that closely matches the needs of a particular industrial sector or type of business

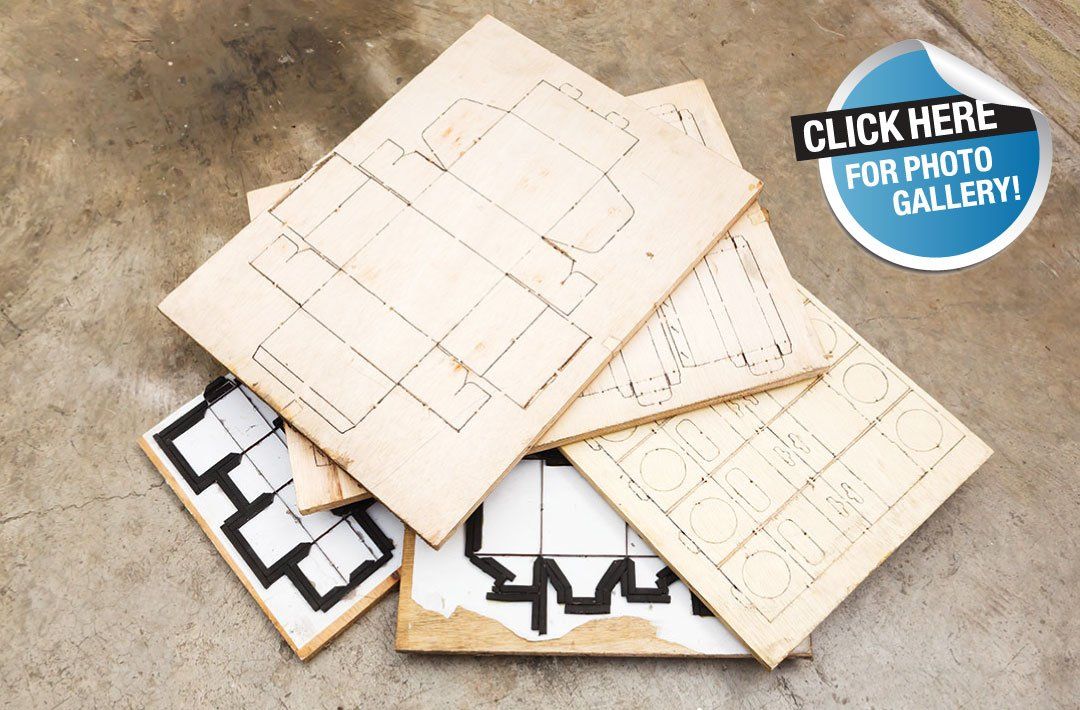

At The Mid-York Press we feature one Bobst Expertcut 106 PER Blanking Diecutter. Both of which boast auto waste stripping and blanking of boxes as well as the technology to speed up the setup process. They also have state of the art register systems, intelligent feeders and quick-change tooling. Our die-cutting is done with laser forged dies. This coupled with thin plate technology and precision stripping boards, give way to high quality diecutting in reduced time.

Along with these die-cutters, we also have a Kluge EHG 22 x 30 foil stamping, embossing and die-cutting press. This machine is excellent for short-run digital work. Low cost dies, faster setup, means more money in your pocket.

Machinery/Technology

- One Bobst Expertcut 106 PER Blanking Diecutters

- Kluge EHG Series Press